The National Corvette Museum’s Bash Event kicked off on Thursday and one of the featured speakers was Corvette Assembly Plant Director Kai Spande. Kai’s updates are always informative and offers enthusiasts some idea of what’s happening on the production side of America’s favorite sportscar.

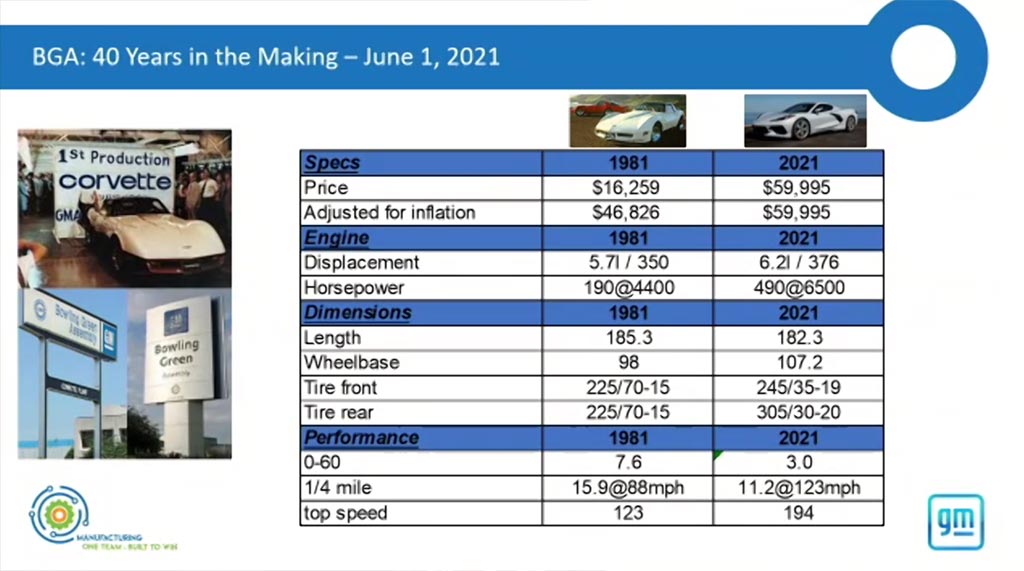

Before going into his presentation, Kai acknowledged that this year marks the 40th anniversary of the Bowling Green Assembly Plant with the first Corvettes coming off the line on June 1st 1981. A celebration for plant employees will hopefully be allowed to happen. Kai offered up this slide showing the differences in the 1981 Corvette to the 2021 model which shows just how far the car has come in the last 40 years:

It’s been a challenge for the workers who are still under strict COVID protocols whenever they enter the building, but he also tells us that they are in the “fourth day of the seventh week where they haven’t had an interruption in production.” Kai tells us that during manufacturing, they are always looking for stability. “We’ve got that for the time being, but around the world, there are a lot of threats we are dealing with.”

Of course the major concern in the automotive industry is the shortage of semiconductors. These are common chips that are used in the auto industry but also in electronics and all kinds of other products. But according to Kai, that’s just one of the challenges they face on a daily basis.

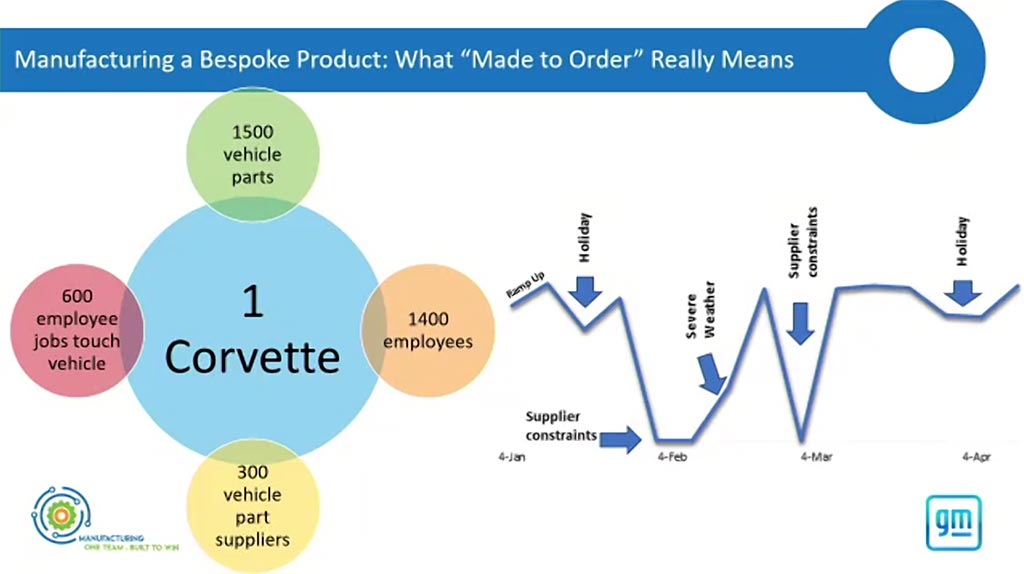

Unlike other models, the Corvette is a “bespoke” product with 300 parts suppliers and 1500 vehicle parts, and if one of those parts becomes unavailable, production stops because you just can’t get that part from somewhere else.

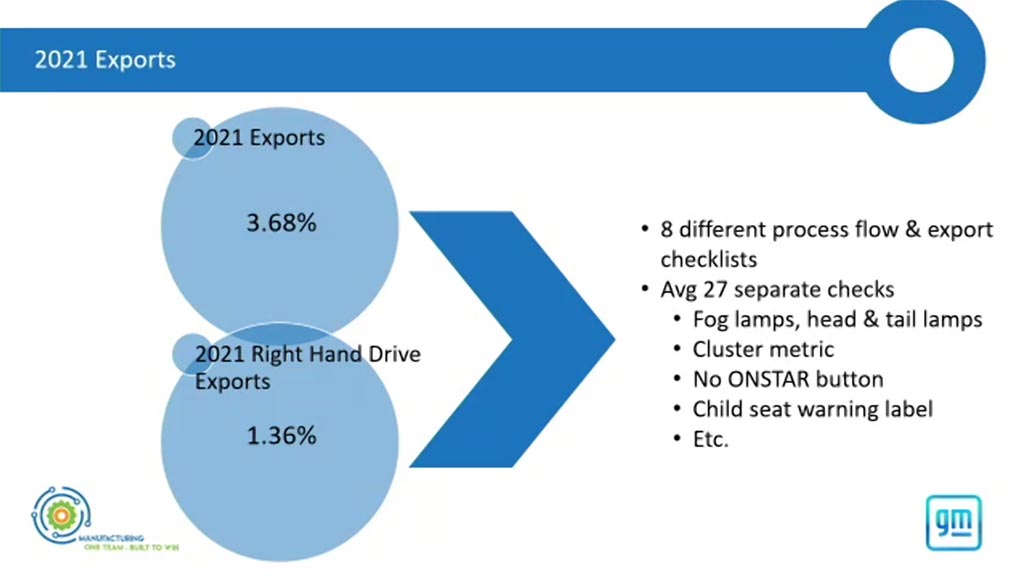

The discussion then turns to some of the interesting things they have been working on inside Bowling Green Assembly. One of the biggest updates is what Kai refers to as the Ambidextrous Journey as the plant is now building Right Hand Drive Corvettes for export to Japan. Kai says that cars have already been built and shipped to customers in Japan. Currently, the 2021 exports are 3.68% of production while those right-hand models make up 1.36% of Corvettes produced at the plant. With 11,000 Corvettes produced, that would be 400 built for export and 149 RHD exports.

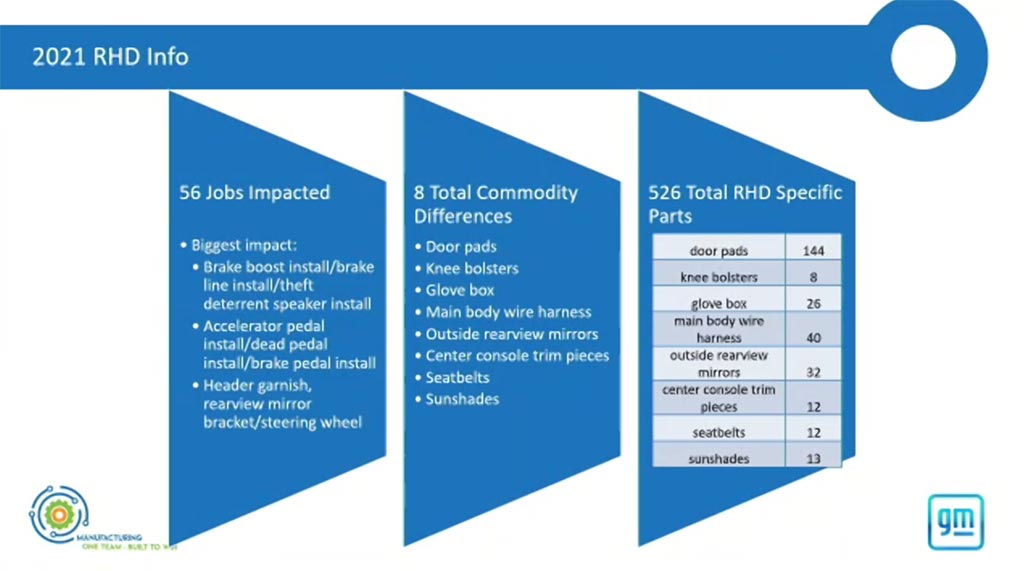

Kai explains the RHD models utilize 8 different process flow and export checklists, and a total of 526 Right Hand Drive specific parts are used during assembly. These two slides share some of the details:

As the plant is home to the Performance Build Center, Kai welcomed the production of the LT4 6.2L supercharged V8 that will be going into the Cadillac CT5-V Blackwing. Those engines will be assembled by hand at the PBC and then shipped to Michigan for production.

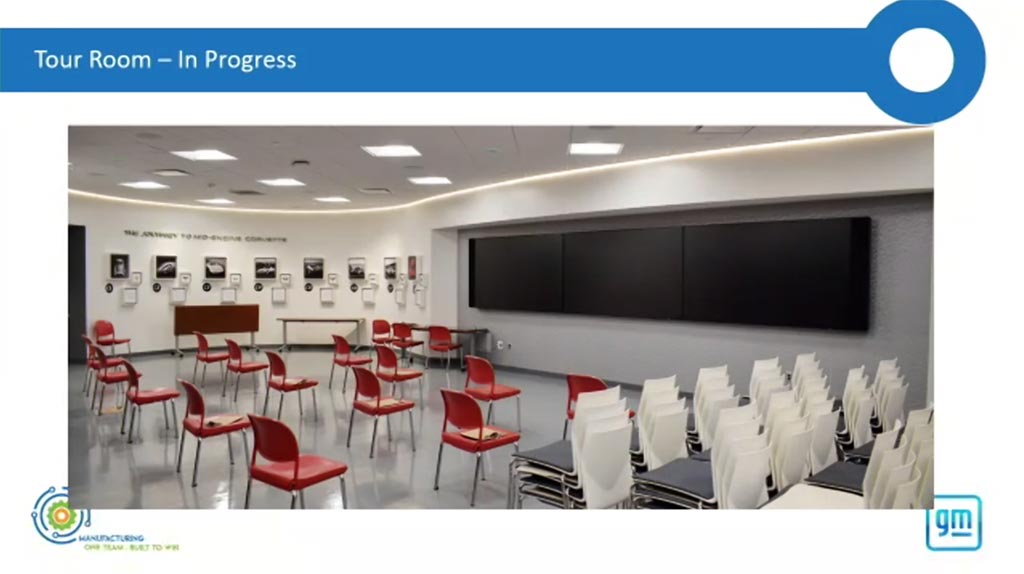

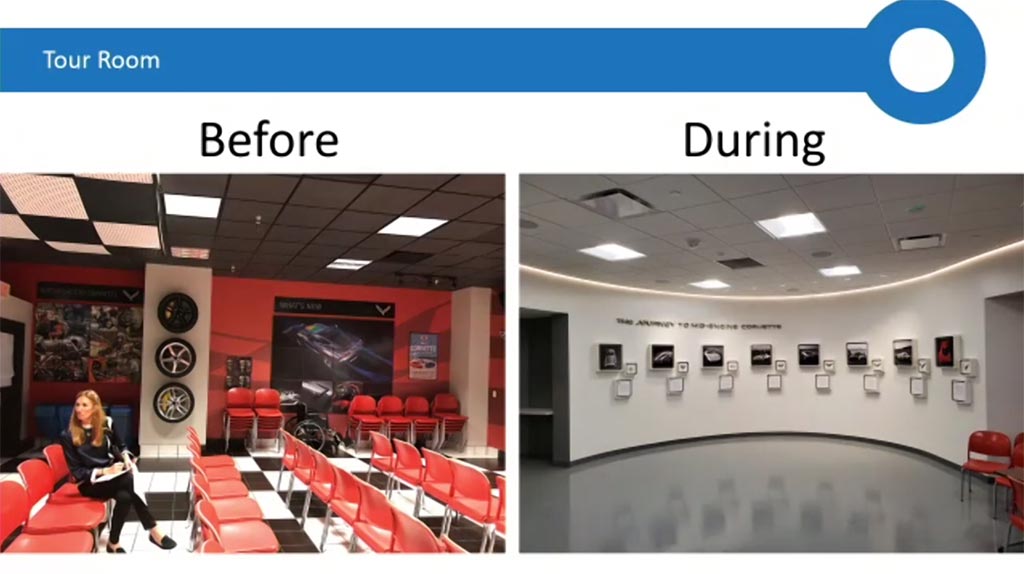

Kai brings up the public tours at the plant he is hoping they will resume. He says that they are still dictated by company and covid restrictions, and only those that can enter the building are there for business purposes. “We desperately want to open the factory to you but our number one priority is keeping employees safe.”

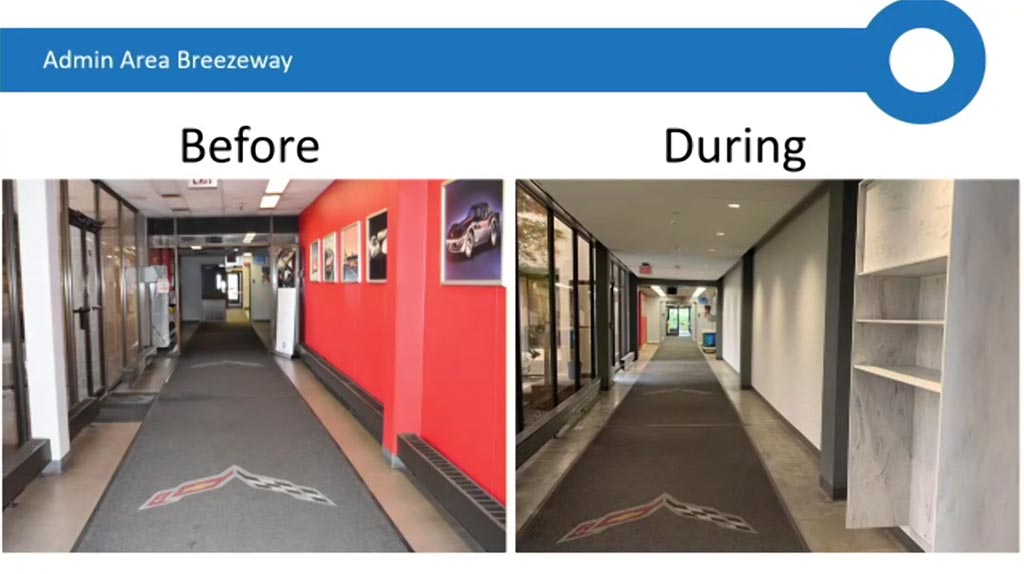

In the meantime, there have been some upgrades made to the plant. The Tour Room has been given a modern makeover with new artwork that shows the transformation from model to model. The Administrative Breezeway which connects the administrative offices to the assembly area has also been undergoing renovation as the slides below show:

Other plant improvements include GM’s journey to sourcing 100% renewable energy by 2030. The Tennessee Valley Authority is building the largest solar site in south-central Kentucky and through the Green Invest program, the Corvette Assembly Plant will receive 28 megawatts of solar power which Kai says is more than enough power to run the plant’s daily operations.

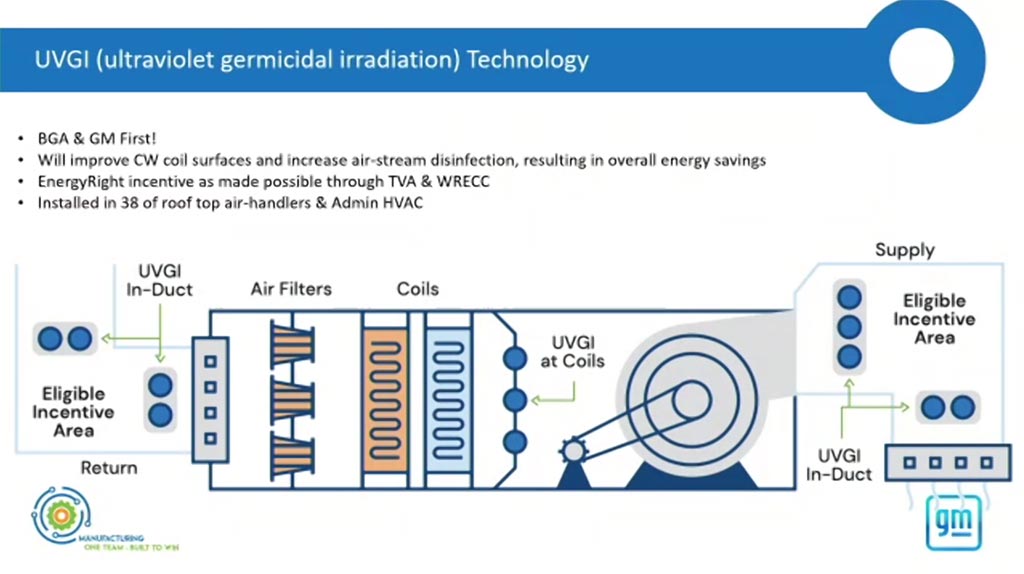

Another highlight and a first for General Motors is the assembly plant’s ultraviolet germicidal irradiation technology that disinfects the air through 38 of the roof top air-handlers.

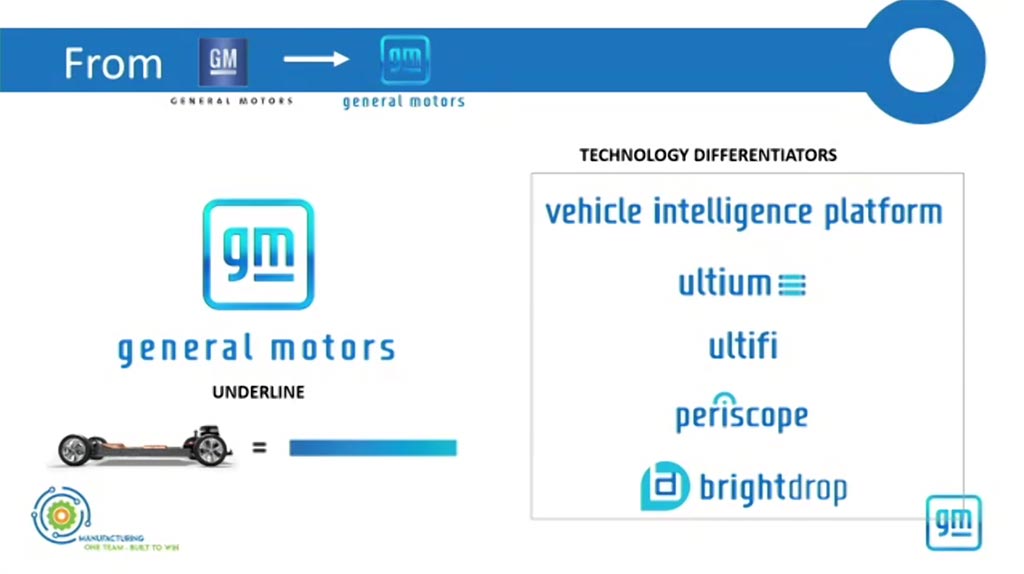

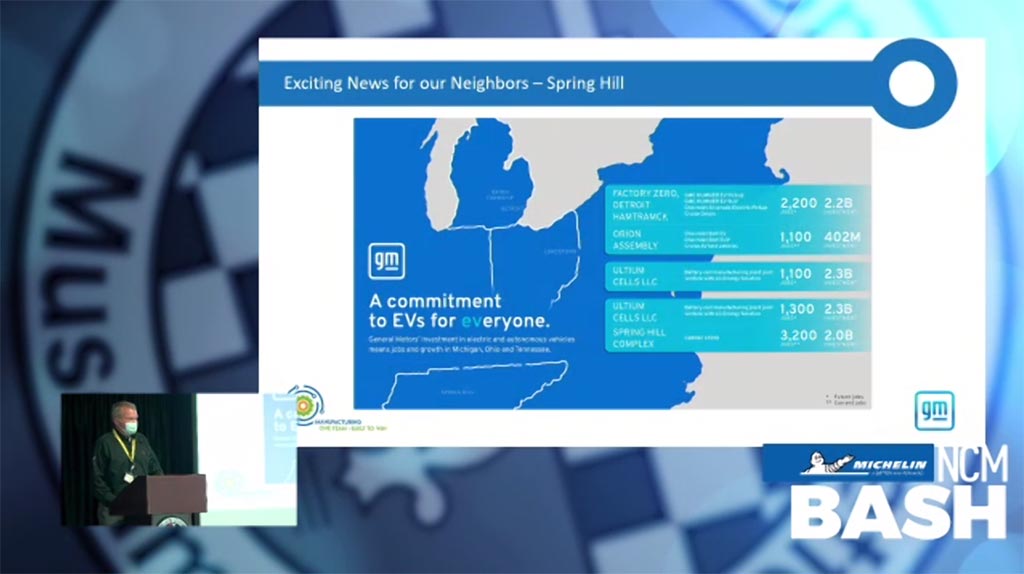

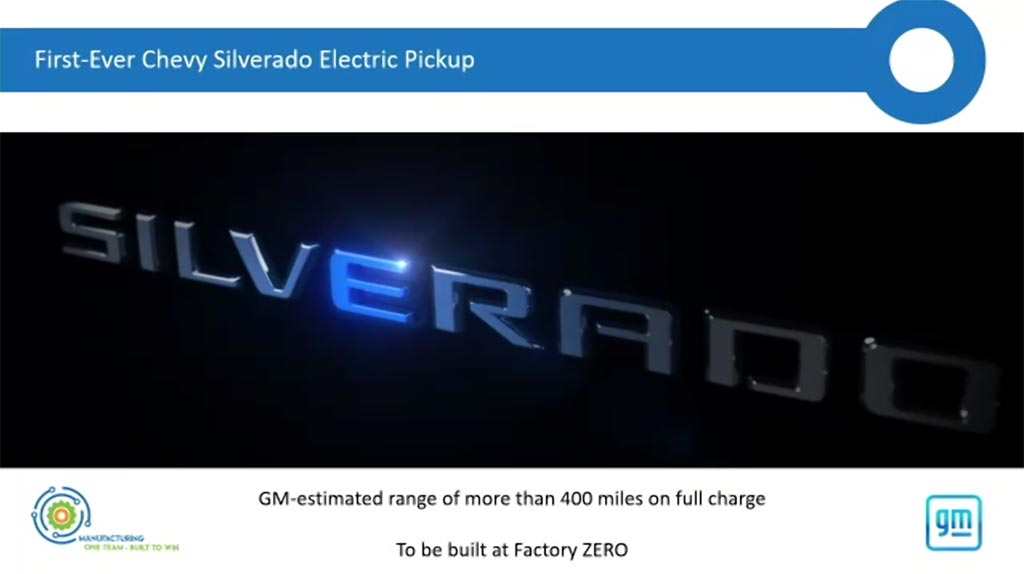

The plant director also talked a good deal about the move to electrification showing GM’s investments with five different plants, and he showed off the new GM logo. He also played the videos of the Will Ferrell SuperBowl ad featuring the Cadillac Lyric as well as the new commercial for the GMC Hummer. Lastly, he showed the Silverado is in the works with an estimated range of 400 miles on a full charge.

Before moving on to the unveiling of the three new colors for 2022, Kai asked for national Corvette seller Mike Furman to come on stage. Kai recognized Mike as he nears his 5,000 Corvette delivery over his career, and as a show of appreciation, the plant director presented him with a signed photo of the Bowling Green Assembly Plant.

We are hoping the National Corvette Museum will make the video of Kai Spande’s presentation available via YouTube, and it will be added here should they choose to do so.

Related:

[PICS] The Three New Colors for the 2022 Corvette Are Officially Revealed at the NCM Bash

National Corvette Museum Dedicates the Wendell Strode Club Room

RUMOR: Is Chevy Preparing to Start Pre-Production on the Widebody C8 Corvette?

-

![[VIDEO] 2024 Corvette E-Ray Roll Races a Lamborghini, Ferrari 488 Pista [VIDEO] 2024 Corvette E-Ray Roll Races a Lamborghini, Ferrari 488 Pista](https://www.corvetteblogger.com/images/content/uploads/2024/04/042424_24-218x150.jpg)

![[PICS] Three New Colors Introduced for the 2025 Corvette [PICS] Three New Colors Introduced for the 2025 Corvette](https://www.corvetteblogger.com/images/content/uploads/2024/04/042424_23-218x150.jpg)

![[PICS] The 2025 Corvette Stingray is Getting a New Standard Z51 Spoiler [PICS] The 2025 Corvette Stingray is Getting a New Standard Z51 Spoiler](https://www.corvetteblogger.com/images/content/uploads/2024/04/042424_12-218x150.jpg)

Why are they producing cars for overseas and right hand drives when they can’t fill the orders here at home? Thought this was an American sports car. Fill the orders you promised here first.

It’s all blah blah blah! Build the damn cars.

I share Larry’s question. I understand establishing a global market, but at the expense of doing damage to your home (USA) market? GM could sell more Corvettes in the US, but their reputation has suffered somewhat due to not being able to keep order commitments. I agree the last couple of years have been abnormal, but some buyers are pretty exasperated with the delays and see the production issues (parts availability, labor strike, Covid restrictions, etc.) as excuses and shortsightedness among leadership.

Fed up with GM. 1ST dropping orders on 2020 not filled then by passing order and TPW schedules to make the highest priced

orders first to try to make sales $ look good and raise stock price. What business are you in selling cars or stock certificates?

I had 3-8-21 TPW bypassed and still not rescheduled??

GM or gm or whatever they are calling themselves now have lost the plot! Build the damn cars here first! Focus on that not the overseas market! Lord have mercy are they morons!

The Tour room at the plant looked better BEFORE the remodel. It was graphically & visually alive, but now looks corporate sterile. Should have left it alone. Sometimes change makes things worse, not better.

I hope not many owners are going through what I am with my 2021 HTC. The day after I picked my corvette I put the top down and when I attempted to put it back up the hooks deployed before the top was closed. I was 1.5 hours from my house. I pushed the top down to get it to latch but there was a warning “top not secure” and you are limited to 58MPH. After driving home I took it back to the dealer another hour away. They contacted GM then replaced parts then more parts. They had my car 22 days. The dealer found a screwdriver had been left In the closer motor area from the factory. GM first offer to me for my trouble was $100 to use for service on the car. The day after I got it back I put the top down and it wouldn’t even move. It was 45 degrees. I told the dealer to send a wrecker that I wasn’t going to drive it that far with the top down. The top worked in the heated shop but they moved it to an unheated area and the top would not close. Manual says 17-32 degrees it will work. The top worked 4-5 times in the next but made a clunking sound when it closed until last week when it deployed the hooks again before it was closed. It has been back in the shop for over a week waiting for GM to figure out what to do. $97,500 for a car that the dealer has no idea how to fix and it appears GM isn’t in any hurry to replace it! Very frustrating! 32 days in the shop and no idea when I will see my car again.

Comments are closed.