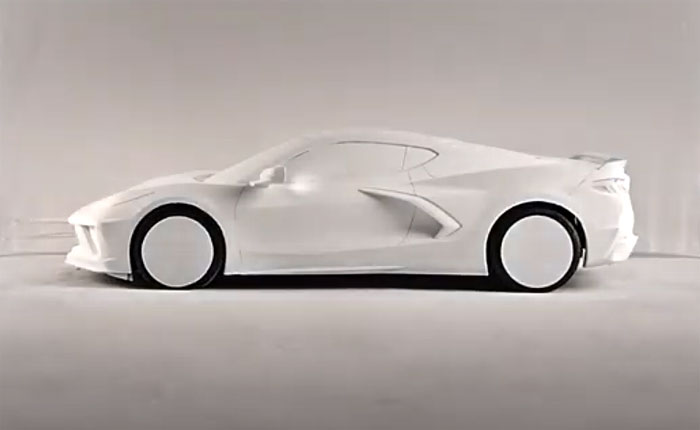

You can give a tip of the cap to 3D printing for helping make it easier for the C8 Corvette to roll down the assembly line in Bowling Green.

GM says it used the relatively new process to build 75 percent of a C8 Corvette prototype, allowing the automaker to make changes on the fly quickly to design parts and make sure they fit together properly. They also used 3D printing to train robots on the production line instead of having to wait on the final parts to be built.

“We can quickly get a prototype part,” Kevin Quinn, GM director of additive design and manufacturing, explained to Car and Driver. “We can iterate that part maybe five times in a week so you make sure you get the right design.”

The 3D printing was especially helpful in the early design of the retractable hardtop, the first-ever for a Corvette, to ensure that the opening and closing procedures were functioning properly.

We don’t have any official word, but it’s likely that the 3D printing was also able to help GM keep costs down for the C8, allowing for its remarkably low $59,995 price tag. The process also helped the automaker more cost-effectively design a right-hand-drive Corvette for overseas markets for the first time.

As for when actual production parts themselves might be 3D-printed, the company says that could happen “very soon,” though such usage would have to be situation-appropriate without compromising safety.

(Photo by Jeffrey Sauger for General Motors)

With GM’s ever-increasing investment in two 3D printing facilities in Warren, Michigan, it’s likely we’ll see more and more usage of this technology. In fact, some GM officials predict a future app or service that would allow owners to download or print parts at home through a subscription service. We could also foresee the day when parts for classic cars, long out of stock, could be built cost-effectively with 3D printers. Since GM says such usage would require higher quality machines than the average owner might have access to, we could envision companies like Mid-America Motorworks stepping in to help out and make the process affordable.

The 3D printers also came in handy in another unexpected way when GM was able to quickly convert them over to manufacture face shields for medical staff during the COVID-19 pandemic.

“We were able to quickly do and quickly turn on with 3D printing in terms of supporting COVID relief efforts and supporting those workers on the front line, as well as, frankly, the folks at our own company as we got back to work to ensure that they’re safe and comfortable when they’re working with face shields,” Quinn said.

Source:

General Motors via CarandDriver.com

Related:

[VIDEO] Corvette Exterior Design Manager Kirk Bennion Brings a C8 Corvette to the Cleveland Institute of Art

[PICS] GM Receives Design Patent for the C8 Corvette Coupe

Corvette Interior Designer Tristen Murphy Discusses the C8’s Interior Design

-

![[PICS] Three New Colors Introduced for the 2025 Corvette [PICS] Three New Colors Introduced for the 2025 Corvette](https://www.corvetteblogger.com/images/content/uploads/2024/04/042424_23-218x150.jpg)

![[PICS] The 2025 Corvette Stingray is Getting a New Standard Z51 Spoiler [PICS] The 2025 Corvette Stingray is Getting a New Standard Z51 Spoiler](https://www.corvetteblogger.com/images/content/uploads/2024/04/042424_12-218x150.jpg)

![[STOLEN] Car Thefts Surged Nationwide in 2023 [STOLEN] Car Thefts Surged Nationwide in 2023](https://www.corvetteblogger.com/images/content/uploads/2024/04/042324_19-218x150.jpg)