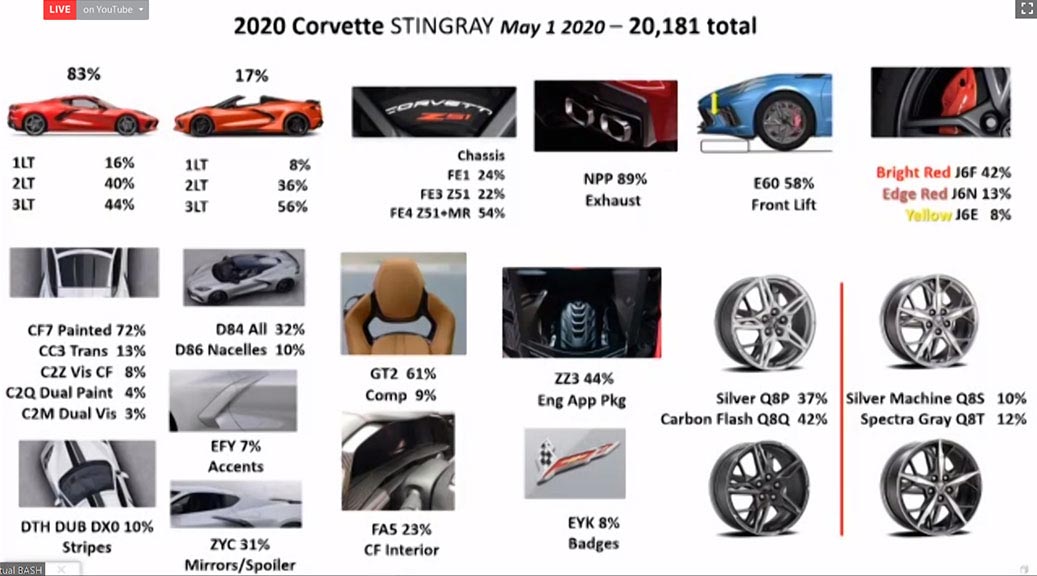

Corvette Product Manager Harlan Charles shared Friday during the National Corvette Museum’s Corvette Team Seminar that previously built 2020 Corvettes plus already accepted dealer orders for 2020 Corvettes total 20,181 possible 2020 Corvettes.

Assuming that the report of a November 2nd model year change proves accurate, here is how we get to 20,000 Corvettes produced during the 2020 model year:

- Normal build rate is 11.5 cars per hour. (NOTE: This figure already accounts for downtime. Additional explanation below.)

- For each 8-hour shift, 92 cars can be built.

- Each shift can build 460 cars per week.

- There are 22 weeks between now and November 2.

- In 22 weeks, one shift can build 10,120 cars.

- That leaves 7,000 cars for a second shift to complete, which would require the second shift running for 15 weeks.

- The second shift only needs to start by July 20 in order for the 17,000 number to be achieved.

Assuming there are no further COVID-19 related disruptions, including supplier-related disruptions, 20,000 Corvettes built for the 2020 model year definitely seems attainable.

Additional Production Volume Information

During the National Corvette Museum’s Ambassador Convention on November 1, 2017, Plant Director, Kai Spande, provided the following production information after the 2017 plant retooling:

- C7 daily production volume prior to retooling: 17.2 units per hour/137 per 8 hour shift

- C7 takt time was approximately 3.5 minutes per station prior to retooling

- C7 daily production volume after retooling: 11.6 units per hour/93 per 8 hour shift

Data source: https://youtu.be/R_dSECWDuDk

Daily production information was also provided during the National Corvette Museum’s Birthday Bash on April 26, 2018.

- C7 daily production volume averaged 116 cars during each 10-hour shift (the plant was on a 4 day/10 hours per day work week at the time)

- It was noted that the pre-retooling production rate used to be roughly 17.5 cars per hour and was now 11.5 cars per hour. (11.5 cars per hour referenced at 20:38 in the video)

Data source: https://youtu.be/v8ZmFF-oaQo

During the NCM’s 25th Anniversary Celebration, the following production information was provided on August 29, 2019.

- The desired takt time is about 4.5 minutes per station.

- 2020 production should start at around 6 minutes takt time.

- The benchmark rate for getting to full speed production is 6 to 7 weeks.

Data source: (starts with my question and Kai Spande’s response at 35:21 in the video) https://youtu.be/TbpdAmCsKkU

Finally, Kai Spande provided a plant update seminar during the NCM’s Virtual Bash on May 28, 2020 and once again stated that takt time is 4.5 minutes per station.

While a target takt time of 4.5 minutes would result in an hourly production volume of 13.33 cars per hour (60/4.5=13.33), the 4.5 minute figure is the target so that the desired net production volume can be 11.5 or 11.6 cars per hour. The 11.5 or 11.6 figure accounts for down time and other interruptions. This goal translates to a net takt time of 5.2 minutes per car, providing the desired volume of 11.54 cars per hour.

Based on the information presented Friday, here’s how we can anticipate 2020 Corvette production breaking down:

Coupes – 16,750

1LT – 2,680

2LT – 6,700

3LT – 7,370

Convertibles – 3,431

1LT – 275

2LT – 1,235

3LT – 1,921

Chassis

FE1 Non-Z51 – 4,843

FE3 Z51 – 4,440

FE3 Z51+MR – 10,898

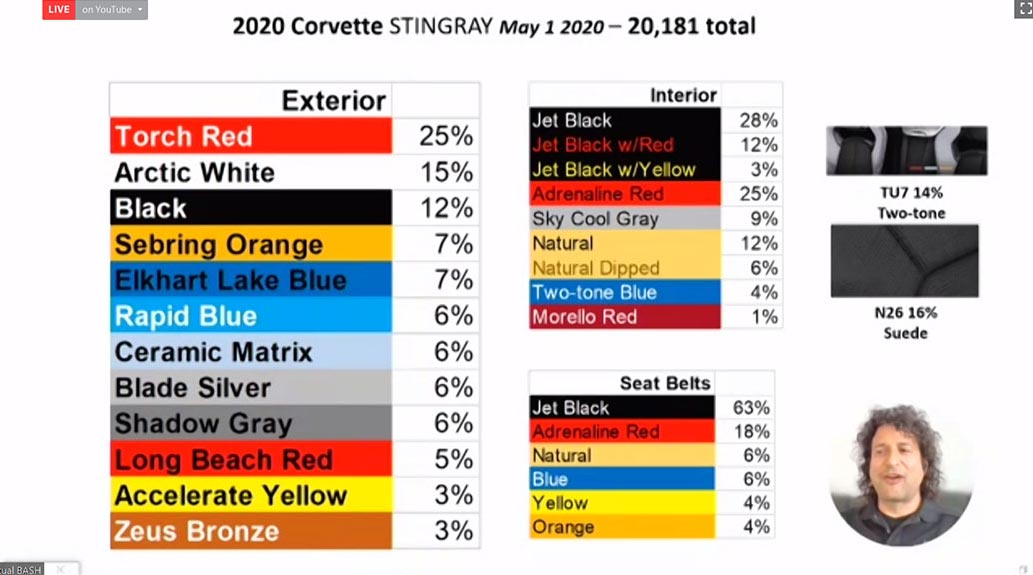

Exterior Colors

(note: numbers on the chart equal 101%, so the following numbers add up to 20,383)

Torch Red – 5,045

Arctic White – 3,027

Black – 2,422

Sebring Orange – 1,413

Elkhart Lake Blue – 1,413

Rapid Blue – 1,211

Ceramic Matrix Gray – 1,211

Blade Silver – 1,211

Shadow Gray – 1,211

Long Beach Red – 1,009

Accelerate Yellow – 605

Zeus Bronze – 605

Interior Colors

Jet Black – 5,651

Jet Black w/Red – 2,422

Jet Black w/Yellow – 605

Adrenaline Red – 5,045

Sky Cool Gray – 1,816

Natural – 2,422

Natural Dipped – 1,211

Two-Tone Blue – 807

Morello Red – 202

Editor’s Note

This post was updated with additional information about the production process based on previously discussed information from representatives of the Bowling Green Assembly Plant.

Source:

National Corvette Museum

Related:

[PICS] The Corvette Team Announces No Price Increases for 2021 Corvettes at the NCM Virtual Bash

Corvette Racing’s Doug Fehan Offers Update at the Virtual NCM Bash

[PICS] Corvette Assembly Plant Manager Kai Spande Provides Production Update During the Virtual NCM Bash

-

![[VIDEO] 2024 Corvette E-Ray Roll Races a Lamborghini, Ferrari 488 Pista [VIDEO] 2024 Corvette E-Ray Roll Races a Lamborghini, Ferrari 488 Pista](https://www.corvetteblogger.com/images/content/uploads/2024/04/042424_24-218x150.jpg)

![[PICS] Three New Colors Introduced for the 2025 Corvette [PICS] Three New Colors Introduced for the 2025 Corvette](https://www.corvetteblogger.com/images/content/uploads/2024/04/042424_23-218x150.jpg)

![[PICS] The 2025 Corvette Stingray is Getting a New Standard Z51 Spoiler [PICS] The 2025 Corvette Stingray is Getting a New Standard Z51 Spoiler](https://www.corvetteblogger.com/images/content/uploads/2024/04/042424_12-218x150.jpg)

Highly doubtful! The factory is way behind now, and the virus will probably cause the factory to reclose before the year is over. GM and the UAW bickering earlier this year really disrupted the production of the C8, many more cars would have been produced if it wasn’t for the strike. Unfortunately, only less than 3,000 have been produced so far, frustrating owners who looked forward to taking delivery of a new Stingray in 2020. Between the lack of vehicles produced, poor quality control issues, and the uncertainty of future work stoppages, the new C8 isn’t off to a good start.

I just want my LT3 Yellow soon I ordered it in July of last year.

They made 15 cars in one day last week.

With all the problems in the world today, and at GM. The best decision might be to wait until next year. Maybe 2021 will be a better year.

need to figure in Downtime every plant has it and July 4th vacation that’s 2 weeks

NEVER!!! They are only doing 5 per hour now. In 2 months of real production they never came close to 11 per hour…

Glad to see they have a plan of how to get the C8 on order built as I have a Convertible on order. Some of the numbers above on Exterior Color are the same that seems very strange as if something doesn’t add up here? I’m very disappointed to see GM is having trouble with their supplier of the High Wing Spoiler, if 18% wanted it what were they planing on? Understand the Ground Effects Kits are available from 2 or 3 different sources? Seems like GM just doesn’t want to deal with what they promised on the Configurator? That doesn’t feel right to me maybe they just want to push the money to the dealers to install the stuff later? Not sure but it stinks to me. May cancel my order because of GM lack of ability to keep their promise in the Configurator, after all if they can’t get it right up front with this car not sure they will get it right going forward.

I’ve added some additional production volume information that should prove helpful:

Additional Production Volume Information

During the National Corvette Museum’s Ambassador Convention on November 1, 2017, Plant Director, Kai Spande, provided the following production information after the 2017 plant retooling:

– C7 daily production volume prior to retooling: 17.2 units per hour/137 per 8 hour shift

– C7 takt time was approximately 3.5 minutes per station prior to retooling

– C7 daily production volume after retooling: 11.6 units per hour/93 per 8 hour shift

Data source:

https://youtu.be/R_dSECWDuDk

Daily production information was also provided during the National Corvette Museum’s Birthday Bash on April 26, 2018.

– C7 daily production volume averaged 116 cars during each 10-hour shift (the plant was on a 4 day/10 hours per day work week at the time)

– It was noted that the pre-retooling production rate used to be roughly 17.5 cars per hour and was now 11.5 cars per hour. (11.5 cars per hour referenced at 20:38 in the video)

Data source:

https://youtu.be/v8ZmFF-oaQo

During the NCM’s 25th Anniversary Celebration, the following production information was provided on August 29, 2019.

– The desired takt time is about 4.5 minutes per station.

– 2020 production should start at around 6 minutes takt time.

– The benchmark rate for getting to full speed production is 6 to 7 weeks.

Data source: (starts with my question and Kai Spande’s response at 35:21 in the video)

https://youtu.be/TbpdAmCsKkU

Finally, Kai Spande provided a plant update seminar during the NCM’s Virtual Bash on May 28, 2020 and once again stated that takt time is 4.5 minutes per station.

While a target takt time of 4.5 minutes would result in an hourly production volume of 13.33 cars per hour (60/4.5=13.33), the 4.5 minute figure is the target so that the desired net production volume can be 11.5 or 11.6 cars per hour. The 11.5 or 11.6 figure accounts for down time and other interruptions. This goal translates to a net takt time of 5.2 minutes per car, providing the desired volume of 11.54 cars per hour.

Comments are closed.