Chevrolet has turned to using “little spies” to make sure the engines going into the 2014 Corvette Stingray and 2014 Silverado are up to par.

Basically, as the engines go through the various stages of building at General Motors’ Tonawanda, New York facility, the process is being documented through an RFID (Radio Frequency Identification) data bolt that has been installed on each engine block and engine head.

After the engine has been through the machining process, the data bolts are scanned to make sure that no steps have been missed and to document that each engine block has no leaks when tested.

Each data bolt holds 2 kilobytes of data, sufficient to document the entire block and head’s manufacturing history.

Workers can use the information to tell in real time when each block and head went through the machining process. If there should be a flaw, they can use this information to figure out if it was just a fluke or if other parts made before and after need to be checked, too, to keep any defective parts from leaving the plant.

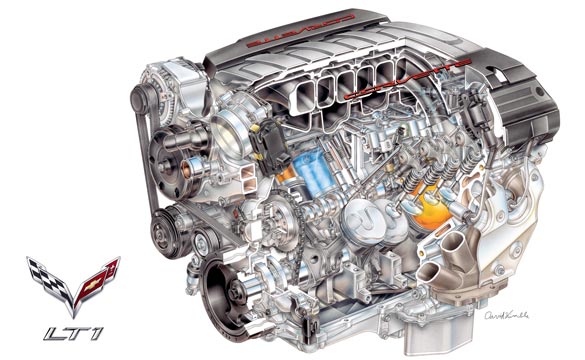

The Gen 5 Small Block is among GM’s first to use these RFID data bolts as a way to measure quality during the machining of the blocks and heads.

The data bolts are collected after assembly has been collected, then reused on other motors coming down the line.

Source:

rfid24-7.com

Related:

[VIDEO] Building the C7 Corvette’s LT1 V8 Engine

OFFICIAL: 2014 C7 Corvette to Feature 450hp 6.2 Liter V8; Revive LT1 Name

Corvette Stingray’s LT1 V8 Engine Makes Wards List of 10 Best Engines

-

![[VIDEO] Chevrolet Was Prepared to Build the C7 and C8 Corvette Simultaneously [VIDEO] Chevrolet Was Prepared to Build the C7 and C8 Corvette Simultaneously](https://www.corvetteblogger.com/images/content/uploads/2024/04/042224_7-218x150.jpg)